Dahaarka qasabadaha

1, oksaydhka uumiga: ku dhufo uumiga biyaha heerkulka sare, dusha sare ee samaynta filimka oksaydhka, xayeysiinta coolant waa wanaagsan tahay, waxay door ka ciyaari kartaa yaraynta khilaafyada, iyadoo laga hortagayo tuubada iyo walxaha goynta u dhexeeya bond, ku habboon si loo farsameeyo birta khafiifka ah.

2, daawaynta nitriding: taabo nitriding dusha sare ah, samaynta lakab adag oo dusha sare ah, oo ku haboon farsamaynta birta kabka, aluminiumka shubka ah iyo walxaha kale ee xidhashada qalabka.

3, uumi + nitriding: faa'iidooyinka dhamaystiran ee labada sare.

4, TiN: dahaarka jaalaha ah ee dahabka ah, qallafsanaanta daahan wanaagsan iyo dufanka, iyo daahan waxqabadka adhesion waa wanaagsan yahay, ku haboon ka baaraandegidda inta badan alaabta.

5, TiCN: daahan buluug cawl, engegnaanta ku saabsan 3000HV, iska caabin kulaylka 400 ° C.

6, TiN + TiCN: daahan huruud ah oo mugdi ah, oo leh qallafsanaan aad u fiican iyo jilicsanaan, oo ku habboon ka baaraandegidda inta badan alaabta.

7, TiAlN: daahan buluug cawl, adayg 3300HV, iska caabin kulaylka ilaa 900 ° C, waxaa loo isticmaali karaa processing-xawaaraha sare.

8, CrN: daahan qalin qalin cawlan, waxqabadka sixin waa ka sarreeya, inta badan loo isticmaalo ka baaraandegidda biraha non-ferrous.

Dahaarka tuubada ayaa saameyn weyn ku leh waxqabadka tuubada, laakiin hadda, soosaarayaasha iyo kuwa wax soo saara waxay iska kaashadaan midba midka kale si loo barto dahaarka gaarka ah, sida LMT IQ, Walther THL, iwm.

Waxyaabaha saameeya taabashada

A. Qalabka tuubada

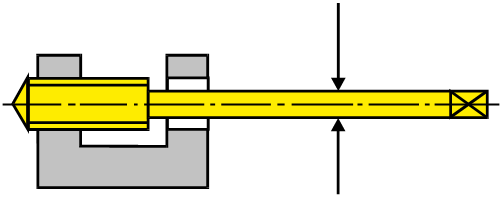

1. Qalabka mishiinka: waxa loo qaybin karaa habab farsamaysan oo toosan iyo mid toosan.Taabashada, toosan ayaa ka fiican habaynta jiifka, farsamaynta toosan waa inay tixgelisaa haddii qaboojinta ku filan tahay.

2, garaacista jeexjeexyada: garaacista waxaa lagula talinayaa in la isticmaalo qashin-qubka khaaska ah, qallafsanaanta mashiinka, xasilloonida wanaagsan ayaa la door bidaa in la doorto shaandhada isku-dhafka ah, liddi ku ah, ilaa inta suurtogalka ah in la doorto dhar jilicsan oo jilicsan oo leh magdhow axial / radial.Isticmaal wadista labajibbaaran mar kasta oo ay suurtagal tahay, marka laga reebo qasabadaha dhexroorka yar

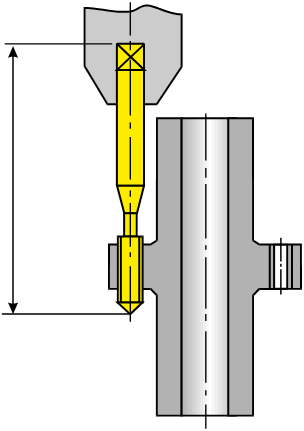

3. Xaaladaha qaboojinta: tuubada, gaar ahaan qasabadaha extrusion, shuruudaha qaboojiyaha waa saliidayn> qaboojin;Isticmaalka dhabta ah, waxaa loo diyaarin karaa iyadoo loo eegayo shuruudaha qalabka mashiinka (marka la isticmaalayo emulsion, waxaa lagu talinayaa in diiradda la saaro 10%).

B. Qalabka shaqada ee la farsamaynayo

1. Qalabka iyo qallafsanaanta shaqada la warshadeeyay: adkaanta qalabka shaqada waa inuu noqdaa mid isku mid ah.Badanaa laguma talinayo in la isticmaalo qasabadaha si loo farsameeyo qaybta shaqada in ka badan HRC42.

2, garaacida godka hoose: qaab dhismeedka godka hoose, dooro qaybta saxda ah;Saxnaanta cabbirka daloolka hoose;Tirada gidaarka godka hoose.

C. Habaynta cabbiraadaha

1, Xawaaraha: Xawaaraha waxaa la bixiyaa iyadoo lagu salaynayo nooca tuubada, maaddada, walxaha warshadaysan iyo adkaanta, faa'iidooyinka iyo khasaarooyinka qalabka tuubada.

Caadi ahaan waxaa loo xushay iyadoo loo eegayo cabirrada ay bixiso soo saaraha tuubada, xawaaraha waa in hoos loo dhigaa xaaladaha soo socda:

▶ Qallafsanaanta qalabka mashiinka ayaa liidata;garaac weyn oo qasabad ah;Qaboojin aan ku filnayn;

▶ Maaddada tuubada ama adayggu maaha mid isku mid ah, sida kala-goysyada alxanka;

▶ Tuubada waa la dheereeyey, ama ul fidsan ayaa la isticmaalaa;

▶ Dufan, qabow dibadda ah;

▶ Hawlgalka gacanta, sida laydhka kursiga, laydhka dhagaxa, iwm.

2, quudin: garaacid adag, quudin = 1 garoon/ leexasho.

Taabasho dabacsan, iyo doorsoomaha magdhowga shank waa ku filan:

Quudinta = (0.95-0.98) garoon/kacaan.

Talooyin ku saabsan xulashada tuubada

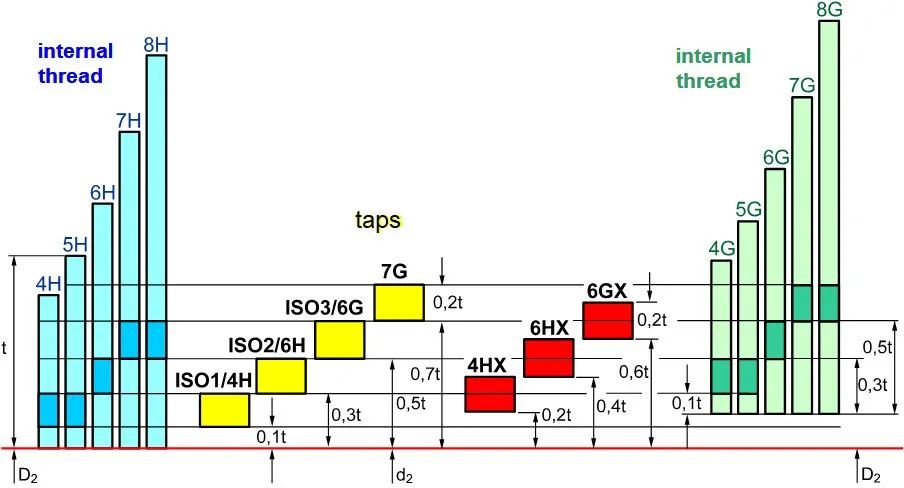

A. U dulqaadashada qasabadaha darajooyinka kala duwan ee saxda ah

Saldhigga xulashada: ma aha oo kaliya iyadoo loo eegayo darajada saxda ah ee dunta in lagu farsameeyo si loo doorto loona go'aamiyo heerka saxda ah ee tuubada

▶ Maaddada iyo adkaanta qalabka shaqada ee la warshadeeyay;

▶ Qalabka tuubada (sida xaaladaha mishiinnada, gacan-qabsiga, giraanta qaboojinta, iwm.);

▶ Tuubada lafteeda saxnaanta iyo khaladka wax soo saarka.

Tusaale ahaan: farsamaynta dunta 6H, ee farsamaynta birta, waxay dooran kartaa tuubada saxda ah ee 6H;Habka birta cawlan ee cawl, sababtoo ah dhexroorka dhexe ee tuubada ayaa si dhakhso ah u xirta, ballaarinta daloolka qulqulka waa mid yar, sidaas darteed waxaa habboon in la doorto tuubada saxda ah ee 6HX, noloshu way fiicnaan doontaa.

Ogow saxnaanta qasabadaha Jabbaan:

▶ Goynta tuubada OSG waxay isticmaashaa nidaamka saxda ah ee OH.Si ka duwan heerka ISO, nidaamka saxda ah ee OH waxa uu ka dhigayaa dhammaan ballaca bandowga dulqaadka xadka ugu hooseeya, 0.02mm kasta oo ah heer sax ah, oo lagu magacaabo OH1, OH2, OH3, iwm.

▶ Tuubada Extrusion OSG waxay isticmaashaa nidaamka saxda ah ee RH, nidaamka saxda ah ee RH wuxuu ku qasbi doonaa dhammaan ballaca dulqaadka xadka ugu hooseeya, 0.0127mm kasta oo ah heer sax ah, oo lagu magacaabo RH1, RH2, RH3 iyo wixii la mid ah.

Sidaa darteed, marka lagu beddelayo tuubada saxda ah ee OH oo lagu beddelayo tuubada saxda ah ee ISO, 6H waa inaan loo qaddarin inay la mid tahay heerka OH3 ama OH4.Waa in lagu go'aamiyaa beddelaad ama iyadoo loo eegayo xaaladda dhabta ah ee macaamilka.

B. Cabirka dibadda ee tuubada

1. Waqtigan xaadirka ah, kuwa ugu badan ee la isticmaalo waa DIN, ANSI, ISO, JIS, iwm.

2, sida waafaqsan shuruudaha processing kala duwan ee macaamilka ama xaaladaha jira si ay u doortaan dhererka ku haboon, dhererka daab iyo xakameen size square.

3. Faragelinta inta lagu jiro hawsha;

Taabo xulashada lix walxood oo aasaasi ah

1, nooca dunta farsamaynta, metric, British, American, iwm.;

2. Nooca dunta godka hoose, dalool ama dalool indho la'aan ah;

3, walxaha workpiece warshadaysan iyo adkaanta;

4, workpiece dhamaystiran dun qoto dheer iyo qoto dheer godka hoose;

5, saxnaanta dunta workpiece;

6, muuqaalka heerka tuubada (shuruudaha gaarka ah ayaa loo baahan yahay in la calaamadiyo).

Waqtiga boostada: Seb-22-2022